I. Industry | Challenges Faced by the Industry

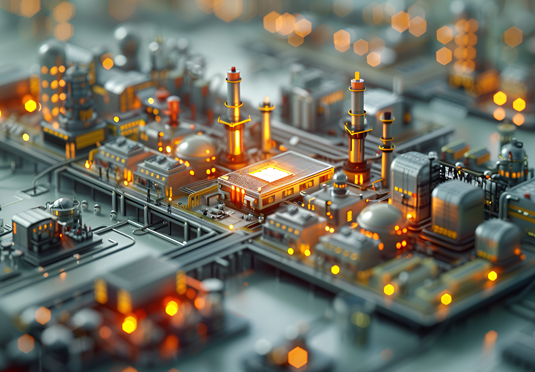

The accelerated improvement of productivity has led to a clearer division of labor in society. Industry 4.0 and the Industrial Internet have given rise to today's smart factories. The high level of digitalization and intelligence in front-end production operations is driving warehousing and logistics toward trends of small batches, multiple frequencies, and highly customized solutions. Coupled with the complexity and diversity of materials, high timeliness of operations, and requirements for high safety and high-precision storage and transportation, this continuously promotes the automation and intelligent upgrading of warehousing and logistics, while also providing more application scenarios for diversified and non-standard customized logistics technologies.

EN

EN